Product

Overview

Overview Graphic

Graphic Technical

Technical Configuration

Configuration Related

Related

Product

- Overview

- Graphic

- Technical

- Configuration

- Related

-

Product Overview

Product OverviewMitech MAW-Y3000B Automatic Pressure Testing Machine, by controlling the high pressure oil pump drives the piston movement, equipped with corresponding auxiliary equipment for ordinary or oil well cement on the compressive strength of mortar test or bending test. With manual and electric hydraulic servo control mode, double precision gap sealing oil cylinder, digital processing, closed loop control technology, performance stable, powerful functions, data processing accurate, solid construction, simple structure, high reliability, simple operation, friendly interface, it is widely used in the field of hardness testing of building materials, quality inspection of quality inspection department and scientific research experiment of institutions of higher learning. It is a professional precision testing instrument that guarantees the quality of construction and improves the safety performance.

Function & application

Function & applicationl Building materials hardness testing

l Teaching experiment of scientific research in Institutions of higher learning

l Material analysis test of scientific research institutions

l Quality inspection link of Quality inspection department

Working Principle

Working PrincipleThe testing machine is the product of combing the testing machine technology with the mechanical transmission technology, the sensor technology, the automation control technology and so on, which is composed of the drive system, the control system, the measurement system. The driving system is mainly used for the beam movement of the testing machine, which can adjust the beam movement through the control valve. The control system regulate the testing machine by the console , getting the state of the test machine and the test parameters through the display screen. The measuring system can conduct the measurement of force, deformation and beam displacement using the sensor, signal amplifiers, photoelectric encoders and data processing systems. This machine can conduct the mechanical performance testing of the material pull, pressure, bending and so on through the coordination of the drive system, control system, measurement system and other subsystems .

Working Conditions

Working Conditionsl Operation Temperature:Ambient temperature~45℃;

l Relative humidity:20%~80%;

l In an environment free from vibration,corrosive medium and high magnetic field

l Installed on a flat basis.

l Power supply voltage fluctuation does not exceed 10% of rated voltage.

Instrument Features

Instrument Featuresl Widely used in ordinary cement mortar or oil well cement compressive strength test or bending test;

l Adopt computer controlling full digital broadband electro-hydraulic valve drive precision hydraulic cylinder, achieve automatic control various modes for the test force, displacement and deformation;

l The one-piece oil source design makes the whole structure more compact and reasonable, and reduces the floor area;

l With display test force, peak test force, test force rate and other functions;

l With the test force cleared, peak hold, parameter setting, the entire process regardless of gear force value measurement, calibration and fine-tuning and other functions;

l 5000-line optoelectronic encoder, the relative high accuracy of displacement;

l High precision and high stability sensor, coupled with high-precision measurement and amplification system to ensure that the test force of high precision;

l Built-in controller to ensure that the test machine can be specimen deformation, test force and displacement of the closed-loop control;

l With a limit protection function, arrived at the limit after the automatic shutdown, to prevent the collision in the middle of the beam caused by overload or even damage to the sensor;

l Built-in control card based on PCI technology can reduce connection, improve test real-time control and real-time acquisition function and improve product stability;

l It can choose load sensor or oil pressure sensor independently to improve the range of test range and the accuracy of force value;

l Automatically according to the size of the load can be switched to the appropriate range to ensure the accuracy of measurement data;

l Zero adjustment, calibration, storage, etc. without any analog adjustment link, the control circuit is highly integrated;

l After testing, test data and test curve automatically saved for later retrieval analysis;

l Consistent with GB, ISO, ASTM, DIN and other relevant domestic and foreign standards.

Operating Method and Attentions

Operating Method and Attentions Instrument Maintenance

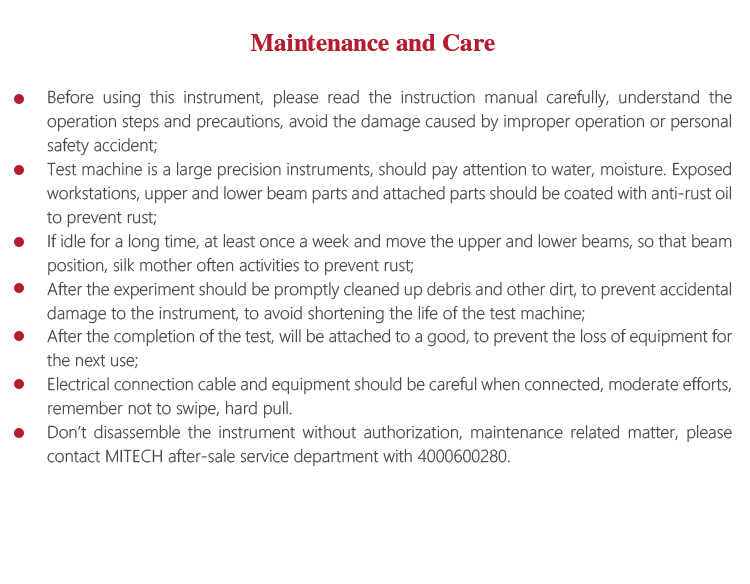

Instrument Maintenancel Before using this instrument, please read the instruction manual carefully, understand the operation steps and precautions, avoid the damage caused by improper operation or personal safety accident;

l Test machine is a large precision instruments, should pay attention to water, moisture. Exposed workstations, upper and lower beam parts and attached parts should be coated with anti-rust oil to prevent rust;

l If idle for a long time, at least once a week and move the upper and lower beams, so that beam position, silk mother often activities to prevent rust;

l After the experiment should be promptly cleaned up debris and other dirt, to prevent accidental damage to the instrument, to avoid shortening the life of the test machine;

l After the completion of the test, will be attached to a good, to prevent the loss of equipment for the next use;

l Electrical connection cable and equipment should be careful when connected, moderate efforts, remember not to swipe, hard pull.

l Don’t disassemble the instrument without authorization, maintenance related matter, please contact MITECH after-sale service department with 4000600280.

-

-

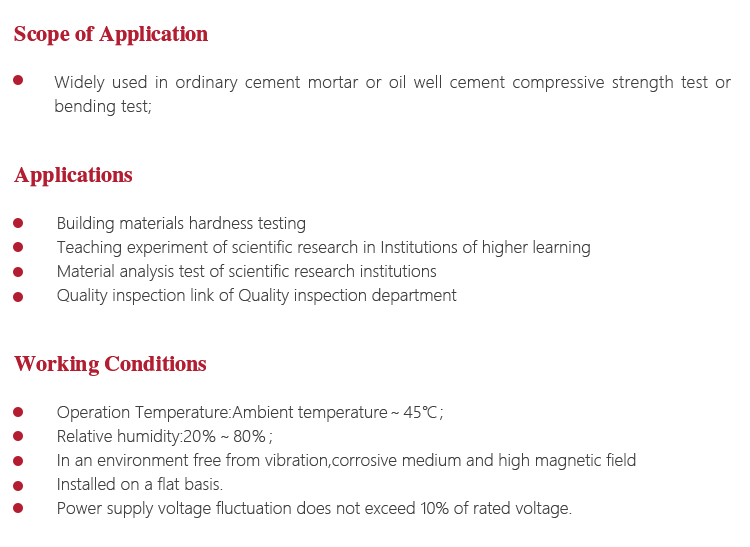

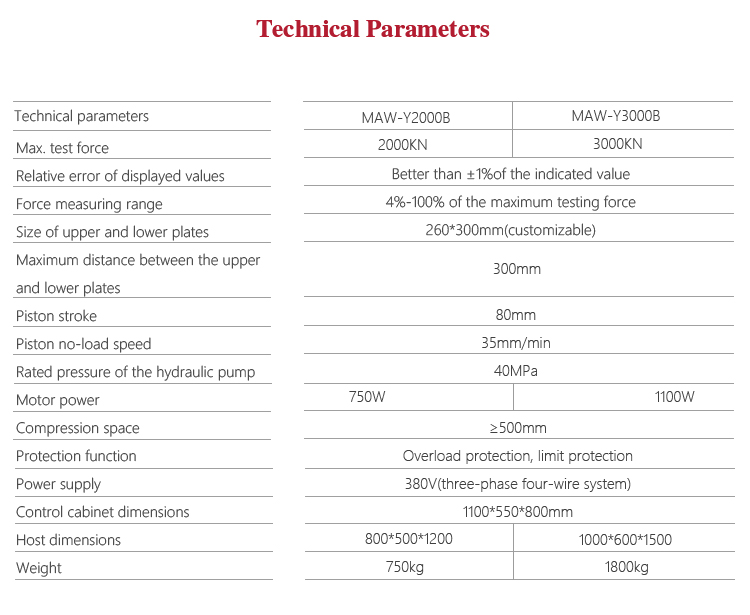

Max. test force 2000KN Relative error of displayed values Better than ±1%of the indicated value Force measuring range 4%-100% of the maximum testing force Size of upper and lower plates 260*300mm(customizable) Maximum distance between the upper and lower plates 300mm Piston stroke 80mm Piston no-load speed 35mm/min Rated pressure of the hydraulic pump 40MPa Motor power 750W Compression space ≥500mm Protection function Overload protection, limit protection Power supply 380V(three-phase four-wire system) Control cabinet dimensions 1100*550*800mm Host dimensions 800*500*1200 Weight 750kg -

-