Product

Overview

Overview Graphic

Graphic Technical

Technical Configuration

Configuration Related

Related

Product

- Overview

- Graphic

- Technical

- Configuration

- Related

-

Product Overview

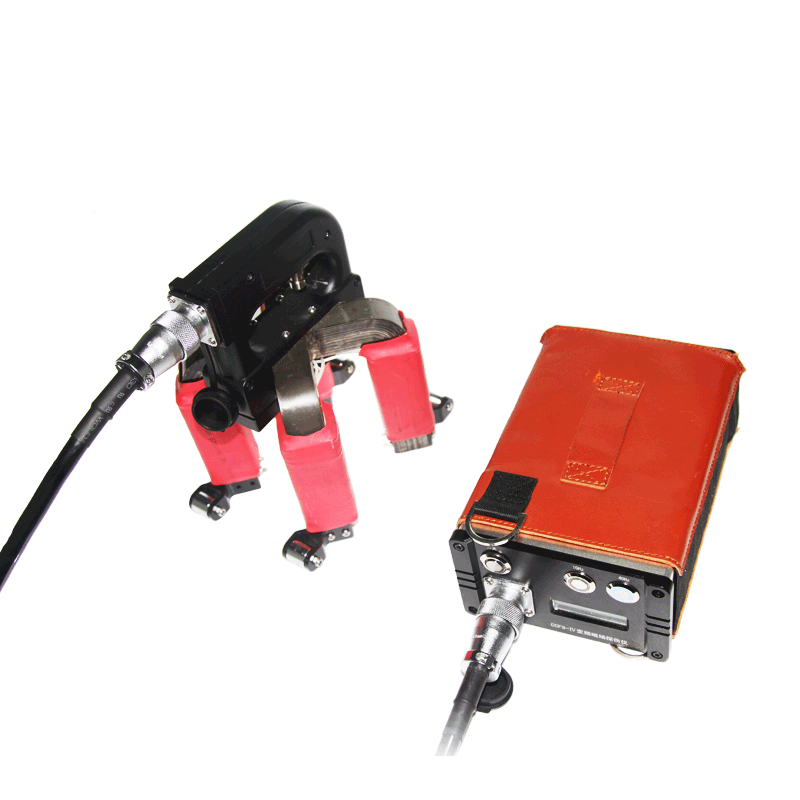

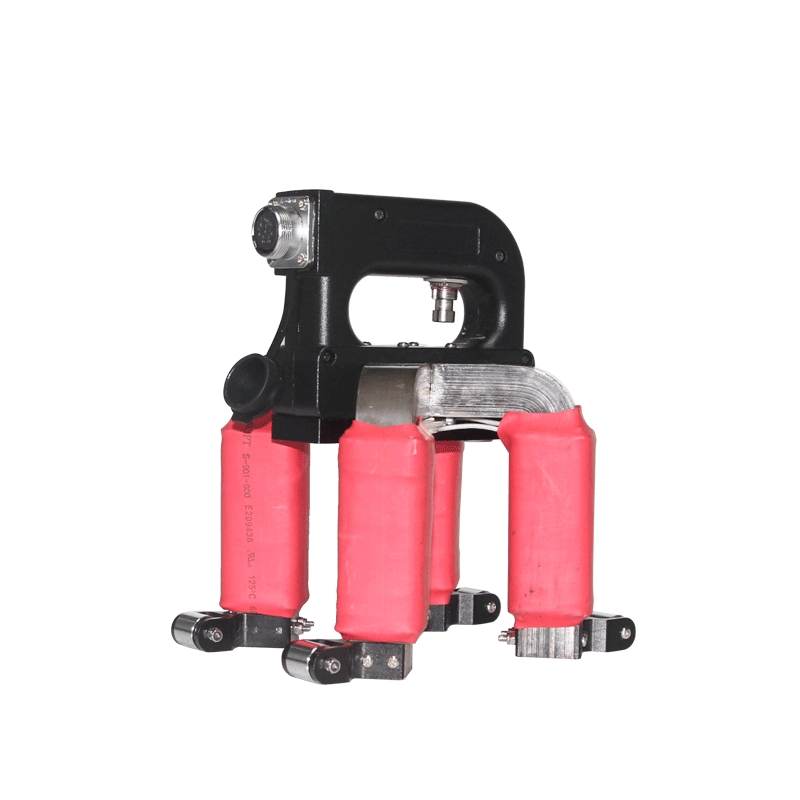

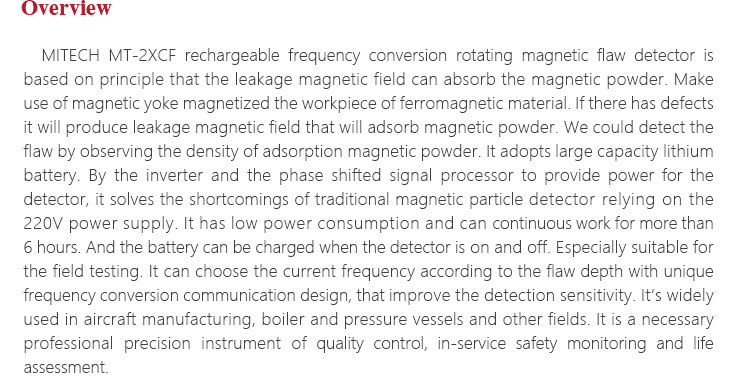

Product OverviewMITECH MT-2XCF rechargeable frequency conversion rotating magnetic flaw detector is based on principle that the leakage magnetic field can absorb the magnetic powder. Make use of magnetic yoke magnetized the workpiece of ferromagnetic material. If there has defects it will produce leakage magnetic field that will adsorb magnetic powder. We could detect the flaw by observing the density of adsorption magnetic powder. It adopts large capacity lithium battery. By the inverter and the phase shifted signal processor to provide power for the detector, it solves the shortcomings of traditional magnetic particle detector relying on the 220V power supply. It has low power consumption and can continuous work for more than 6 hours. And the battery can be charged when the detector is on and off. Especially suitable for the field testing. It can choose the current frequency according to the flaw depth with unique frequency conversion communication design, that improve the detection sensitivity. It’s widely used in aircraft manufacturing, boiler and pressure vessels and other fields. It is a necessary professional precision instrument of quality control, in-service safety monitoring and life assessment.

Function & application

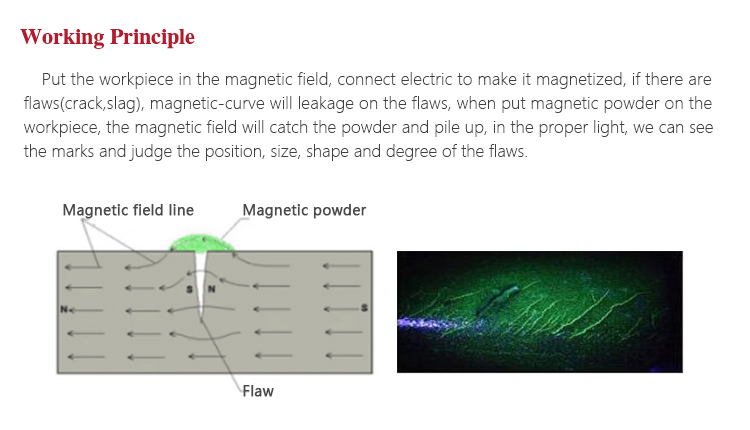

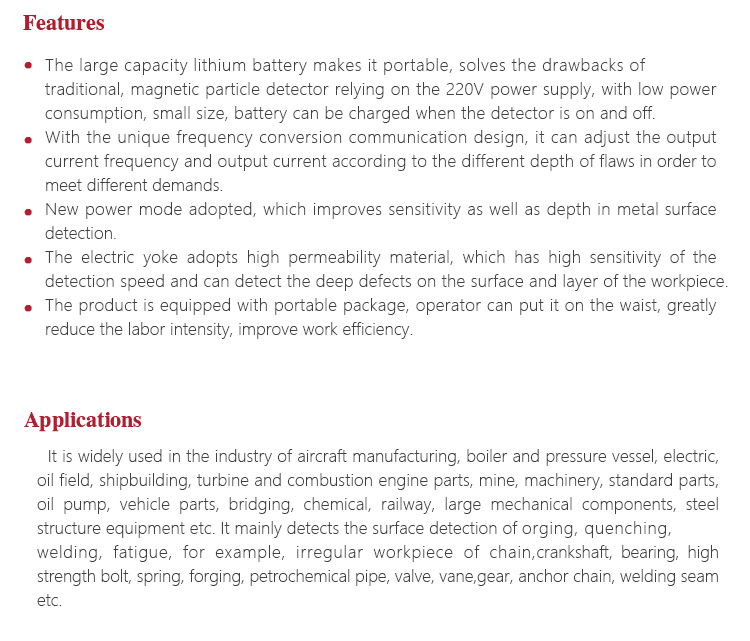

Function & application Working Principle

Working PrinciplePut the workpiece in the magnetic field, connect electric to make it magnetized, if there are flaws(crack,slag), magnetic-curve will leakage on the flaws, when put magnetic powder on the workpiece, the magnetic field will catch the powder and pile up, in the proper light, we can see the marks and judge the position, size, shape and degree of the flaws.

Working Conditions

Working Conditions Instrument Features

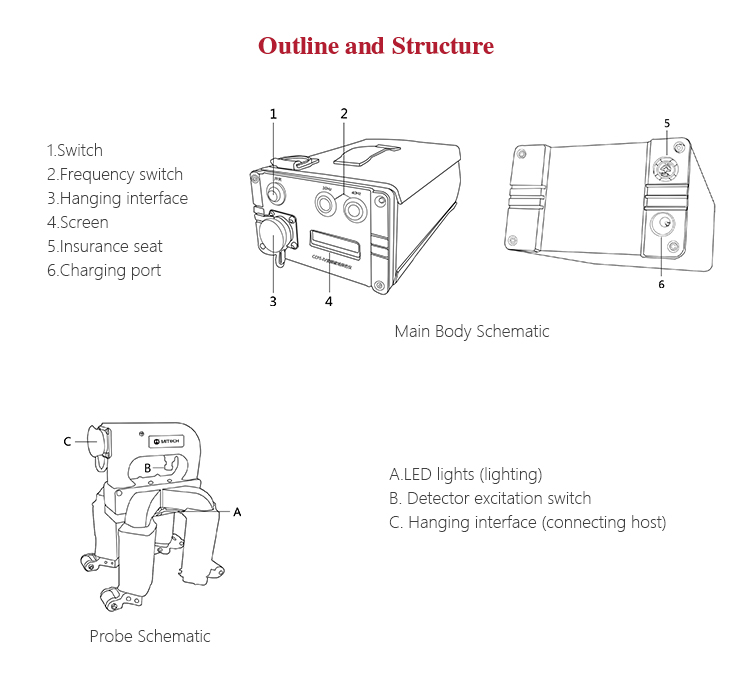

Instrument Featuresl The large capacity lithium battery makes it portable, solves the drawbacks of traditional, magnetic particle detector relying on the 220V power supply, with low power consumption, small size, battery can be charged when the detector is on and off.

l With the unique frequency conversion communication design, it can adjust the output current frequency and output current according to the different depth of flaws in order to meet different demands.

l New power mode adopted, which improves sensitivity as well as depth in metal surface detection.

l The electric yoke adopts high permeability material, which has high sensitivity of the detection speed and can detect the deep defects on the surface and layer of the workpiece.

l The product is equipped with portable package, operator can put it on the waist, greatly reduce the labor intensity, improve work efficiency.

Operating Method and Attentions

Operating Method and Attentions Instrument Maintenance

Instrument Maintenancel In order to protect the storage performance of lithium battery, you should charge the battery as soon as possible when it undervoltage.

l Regular charge is needed if not used for long, in case of damages caused by damp in order to keep its life and working time.

l Avoid no-load working so as to protect the instrument although the instrument has a good no-load over-current protection circuit function.

l The end face and workpiece should be stable contact in order to achieve the best result when you detect the flaw.

l The probe should be avoid collision, drop and keep it clean.

l If you find the probe line package fever is serious, must be immediately stop using, troubleshooting and re-enable after maintenance otherwise it will damage the probe.

l Turn off the power switch when the instrument is not used.

l Slightly operate the key. Too much oil and muddy water fingers should not touch the instrument.

l Oil, dust, adhesion will increase the aging equipment. After using, please use a soft dry cloth clean the oil, dust on the surface. It is usually kept in dry and ventilated place and avoid high temperature, rain, moisture.

l Don’t disassemble the instrument without authorization, maintenance related matters please contact MITECH after-sale service department, 4000600280

-

-

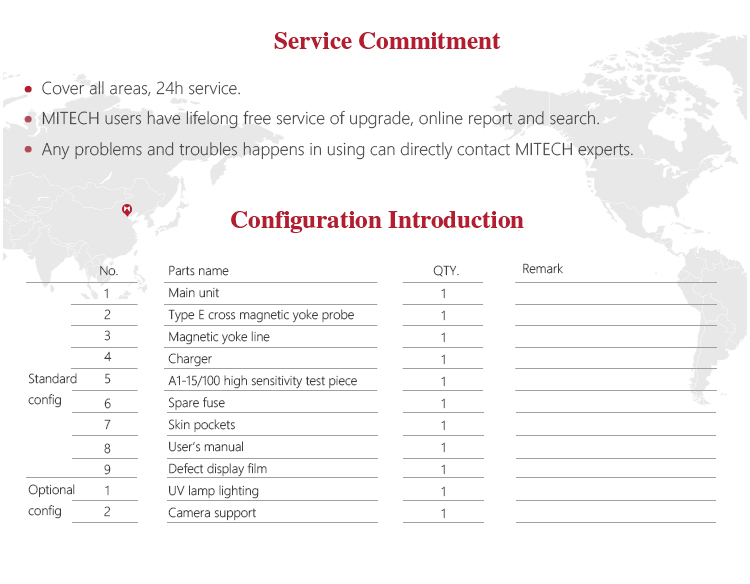

Lifting ≥216N (no less than 22kg) Integrative sensitivity type A 15/100 standard specimen, artificial notch clearly showed Lighting white Working voltage 12.6V Output curve AC Electromagnetic yoke weight 3.75kg Battery voltage 18V Battery capacity 10Ah Charging limited voltage 21V Power supply 220V, 50Hz Charging time 4-5h Continuous working hours >6h Dimension 158mm×118mm×84mmContinuous working hours Weight 1.7kg -

-