Product

Overview

Overview Graphic

Graphic Technical

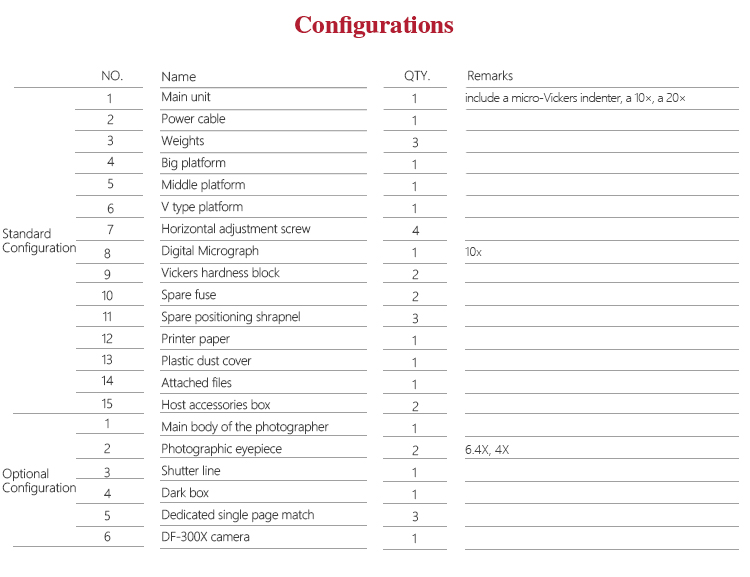

Technical Configuration

Configuration Related

Related

Product

- Overview

- Graphic

- Technical

- Configuration

- Related

-

Product Overview

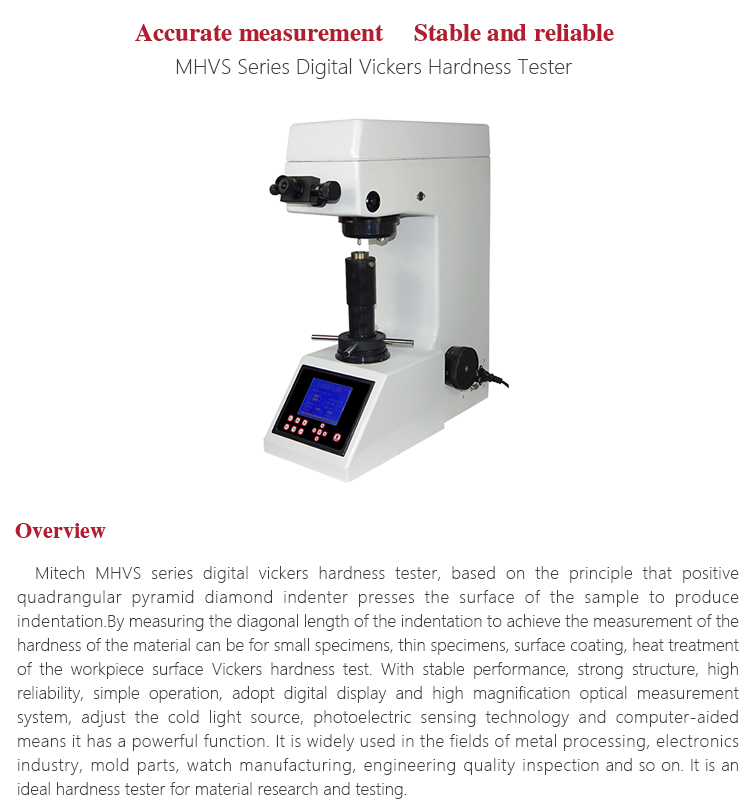

Product OverviewMitech MHVS series digital vickers hardness tester, based on the principle that positive quadrangular pyramid diamond indenter presses the surface of the sample to produce indentation.By measuring the diagonal length of the indentation to achieve the measurement of the hardness of the material can be for small specimens, thin specimens, surface coating, heat treatment of the workpiece surface Vickers hardness test. With stable performance, strong structure, high reliability, simple operation, adopt digital display and high magnification optical measurement system, adjust the cold light source, photoelectric sensing technology and computer-aided means it has a powerful function. It is widely used in the fields of metal processing, electronics industry, mold parts, watch manufacturing, engineering quality inspection and so on. It is an ideal hardness tester for material research and testing.

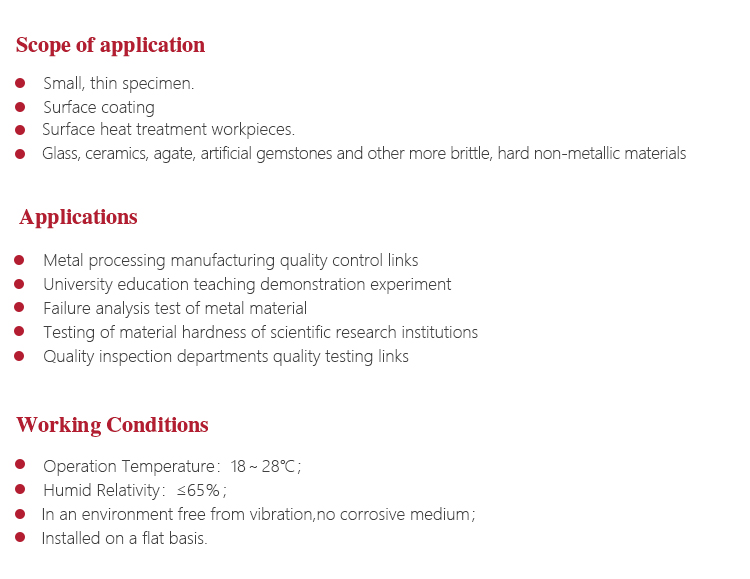

Function & application

Function & applicationSmall, thin specimen.

Surface heat treatment workpieces.

Surface coating

Glass, ceramics, agate, artificial gemstones and other more brittle, hard non-metallic materials

Working Principle

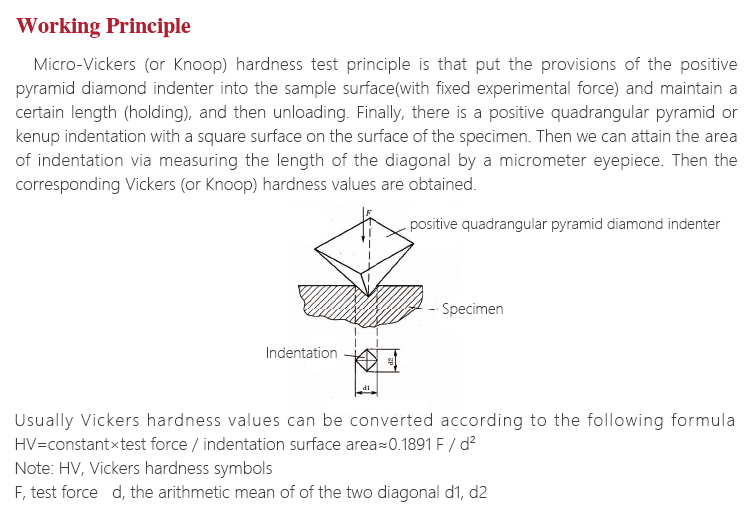

Working PrincipleMicro-Vickers (or Knoop) hardness test principle is that put the provisions of the positive pyramid diamond indenter into the sample surface(with fixed experimental force) and maintain a certain length (holding), and then unloading. Finally, there is a positive quadrangular pyramid or kenup indentation with a square surface on the surface of the specimen. Then we can attain the area of indentation via measuring the length of the diagonal by a micrometer eyepiece. Then the corresponding Vickers (or Knoop) hardness values are obtained.

Usually Vickers hardness values can be converted according to the following formula

HV=constant×test force / indentation surface area≈0.1891 F/d2

Note:

HV, Vickers hardness symbols

F, test force

d, the arithmetic mean of of the two diagonal d1, d2

Working Conditions

Working ConditionsOperation Temperature:18~28℃;

Relative Humidity:≤65%;

In an environment free from vibration,no corrosive medium.

Installed on a flat basis

Instrument Features

Instrument FeatureslWidely used in micro-specimen, thin specimen, surface coating, heat treatment of workpiece surface samples and etc.Vickers hardness test to meet different demands of scientific research institutions, precision machining and quality inspection departments and other materials research;

Light mechanical and electrical integration of high-tech products, high efficiency;

Equipped with a variety of small load Vickers hardness scale spare;

Adopt electronic automatic loading system to control the main test force, eliminating the need to load the weight, the operation more convenient;

Support Brinell, Vickers and other hardness units convert;

Innovative, rugged construction, high reliability, easy to operation, intuitive reading, high efficiency;

Equipped with high-speed thermal printer, real-time print test results;

Adopt large-screen LCD liquid crystal display, easy to operate, visually display the test results;

Adopt high magnification optical sensing system and high precision photoelectric sensing technology, the test point positioning is accurate, the test result is more accurate;

Adopt diamond indenter, durable and accurate;

Adjustable cold light source measurement system that can control the light strength through the software;

Optional photographic device, can be achieved on the measured indentation and material microstructure to shoot for later analysis;

With ISO 6507, ASTM E92, JIS Z2244, GB/T4340.2 and other relevant domestic and foreign standards

Operating Method and Attentions

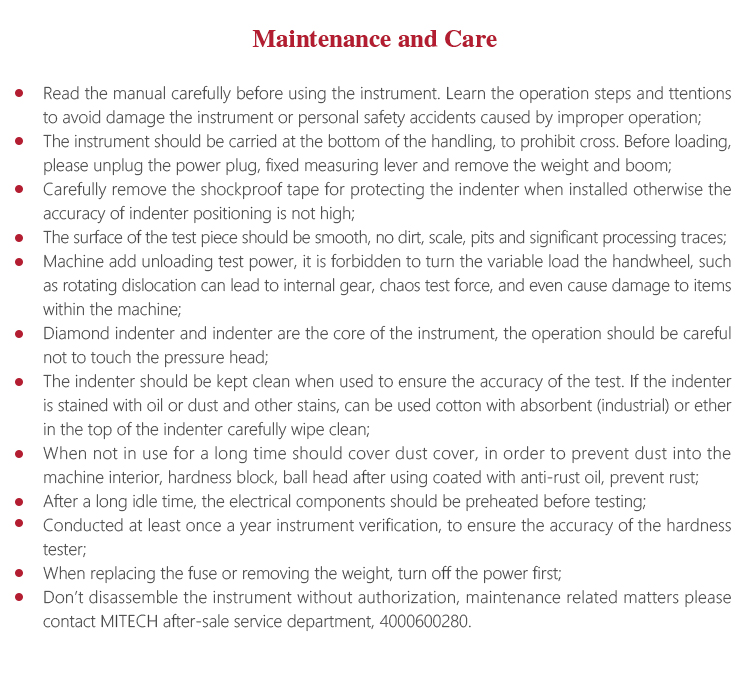

Operating Method and Attentions Instrument Maintenance

Instrument MaintenanceRead the manual carefully before using the instrument. Learn the operation steps and attentions to avoid damage the instrument or personal safety accidents caused by improper operation;

The instrument should be carried at the bottom of the handling, to prohibit cross. Before loading, please unplug the power plug, fixed measuring lever and remove the weight and boom;

Carefully remove the shockproof tape for protecting the indenter when installed otherwise the accuracy of indenter positioning is not high;

The surface of the test piece should be smooth, no dirt, scale, pits and significant processing traces;

Machine add unloading test power, it is forbidden to turn the variable load the handwheel, such as rotating dislocation can lead to internal gear, chaos test force, and even cause damage to items within the machine;

Diamond indenter and indenter are the core of the instrument, the operation should be careful not to touch the pressure head

The indenter should be kept clean when used to ensure the accuracy of the test. If the indenter is stained with oil or dust and other stains, can be used cotton with absorbent (industrial) or ether in the top of the indenter carefully wipe clean

When not in use for a long time should cover dust cover, in order to prevent dust into the machine interior, hardness block, ball head after using coated with anti-rust oil, prevent rust;

After a long idle time, the electrical components should be preheated before testing

Conducted at least once a year instrument verification, to ensure the accuracy of the hardness tester

When replacing the fuse or removing the weight, turn off the power first;

Don’t disassemble the instrument without authorization, maintenance related matters please contact MITECH after-sale service department, 4000600280

-

-

Test force 2.94N、4.9N、9.8N、19.6N、29.4N、49N Measurement range 40HV0.3~2500HV5 Hardness symbol HV0.3、HV0.5、HV1、HV2、HV3、HV5 The conversion mode of the head and the objective lens Manual operation Loading and unloading mode Automatic operation Magnification of measuring microscope 200x(testing) 100x(observing) Minimum detection unit 0.01μm Maximum height of applicable materials 160mm Test to secure the load time 0~60s Maximum distance from the center of the head to the machine wall 135mm Display LCD digital display Power supply AC220V/50Hz Dimension of Exterior 540*220*650mm Machine weight 40kg -

-