Product

Overview

Overview Graphic

Graphic Technical

Technical Configuration

Configuration Related

Related

Product

- Overview

- Graphic

- Technical

- Configuration

- Related

-

Product Overview

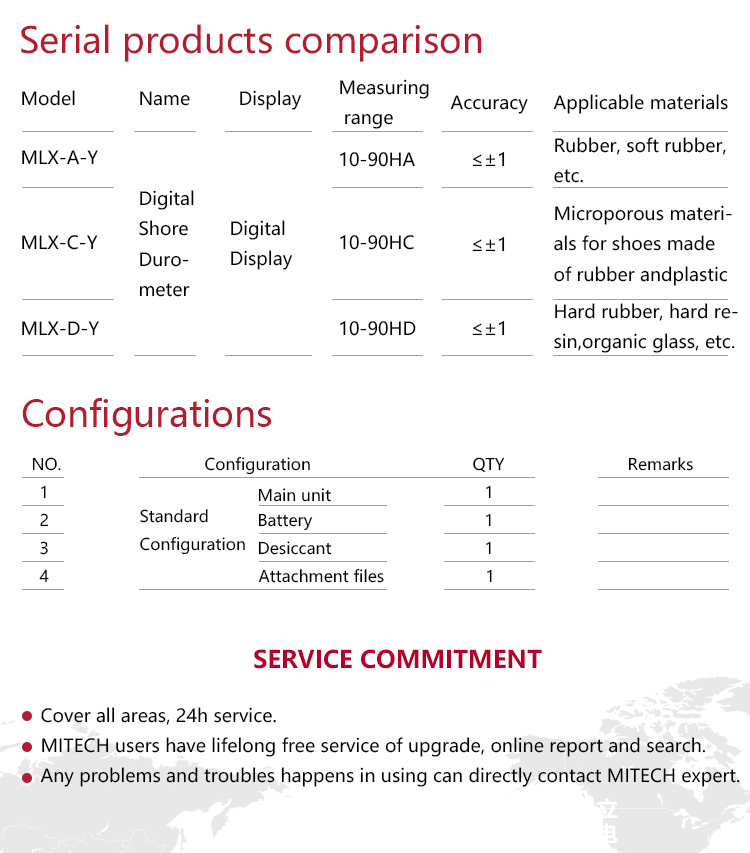

Product OverviewMITECH MLX-A、C、D Digital Shore Rubber Durometer is simple, compact and portable, the reading is intuitive, and it is easy to use. It can be measured by hand or placed on the supporting load frame. It is widely used in the hardness measurement of rubber and plastic.

Function & application

Function & application-

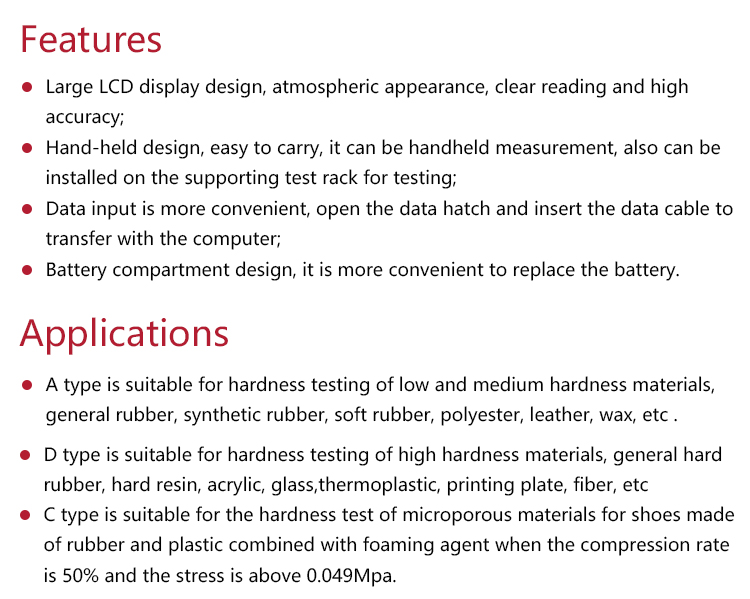

A type is suitable for hardness testing of low and medium hardness materials, general rubber, synthetic rubber, soft rubber, polyester, leather, wax, etc .

-

D type is suitable for hardness testing of high hardness materials, general hard rubber, hard resin, acrylic, glass, thermoplastic, printing plate, fiber, etc

-

C type is suitable for the hardness test of microporous materials for shoes made of rubber and plastic combined with foaming agent when the compression rate is 50% and the stress is above 0.049Mpa.

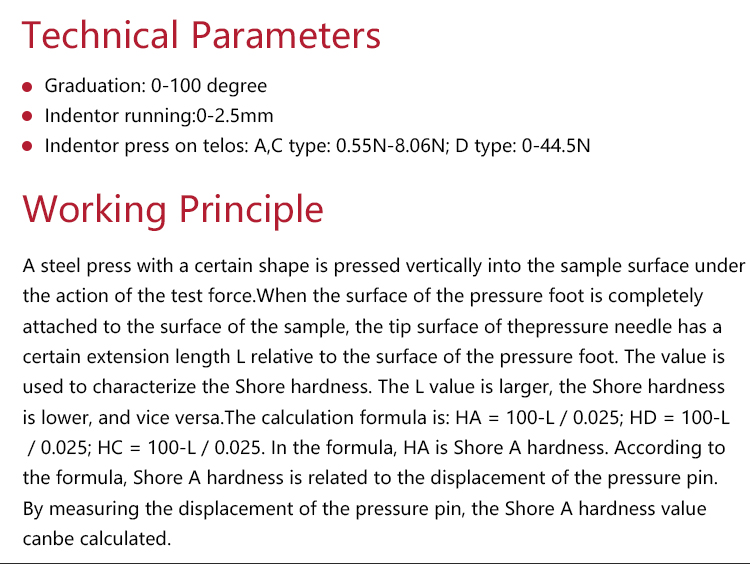

Working Principle

Working PrincipleA steel press with a certain shape is pressed vertically into the sample surface under the action of the test force. When the surface of the pressure foot is completely attached to the surface of the sample, the tip surface of the pressure needle has a certain extension length L relative to the surface of the pressure foot. The value is used to characterize the Shore hardness. The L value is larger, the Shore hardness is lower, and vice versa.

The calculation formula is: HA = 100-L / 0.025; HD = 100-L / 0.025; HC = 100-L / 0.025. In the formula, HA is Shore A hardness. According to the formula, Shore A hardness is related to the displacement of the pressure pin. By measuring the displacement of the pressure pin, the Shore A hardness value can be calculated.

Working Conditions

Working Conditions Instrument Features

Instrument Features-

Large LCD display design, atmospheric appearance, clear reading and high accuracy;

-

Hand-held design, easy to carry, it can be handheld measurement, also can be installed on the supporting test rack for testing;

-

Data input is more convenient, open the data hatch and insert the data cable to transfer with the computer;

-

Battery compartment design, it is more convenient to replace the battery.

Operating Method and Attentions

Operating Method and Attentions-

Place the sample on a sturdy surface, hold the instrument so that the pressure pin is at least 12mm away from the edge of the sample, and press the pressure foot on the sample steadily until the pressure foot and the sample are completely released within 1s;

-

Measure the hardness value 5 times at different positions at least 6mm away from the measuring point, and take the average value (the distance between the measuring points of the microporous material is at least 15mm);

-

In order to stabilize the measurement conditions and improve the measurement accuracy, the hardness tester device should be measured on the same type of measurement rack.

Instrument Maintenance

Instrument Maintenance-

After the durometer is used, it should be wiped clean and placed in the instrument box, and placed in a dry place to prevent moisture;

-

The measurement rack should be wiped frequently, and a small amount of anti-rust oil should be applied to prevent rust, and the No. 20 motor oil should be added to the moving parts;

-

The durometer should be submitted to the inspection regularly according to JJG304-89.

-

-

-

Graduation 0-100 degree Indentor running 0-2.5mm Indentor press on telos A,C type: 0.55N-8.06N; D type: 0-44.5N -

-