Mitech MEW-G1000 Microcomputer Screen Series Steel

Mitech

4% -100% of Maximum test power

≤ ± 1% of indication

4500kg

1060*660*2950mm

Product

Overview

Overview Graphic

Graphic Technical

Technical Configuration

Configuration Related

Related

Product

- Overview

- Graphic

- Technical

- Configuration

- Related

-

Product Overview

Product OverviewMitech MEW-G microcomputer screen series steel wire tensile testing machine,by controlling the high-pressure pump to drive the screw movement,mainly for the prestressed steel strand tensile strength test and analysis.It is characterized by high precision gap sealing cylinder, microcomputer display technology, digitized processing and high precision data acquisition and control technology. Its performance is stable, powerful, accurate data processing, strong structure, simple structure, high reliability, simple operation and friendly interface.Widely used in metal and non-metallic processing industry, quality inspection departments quality testing, scientific research and other areas of higher education institutions.It is the necessary professional precision testing equipment for improving production efficiency and saving production costs.

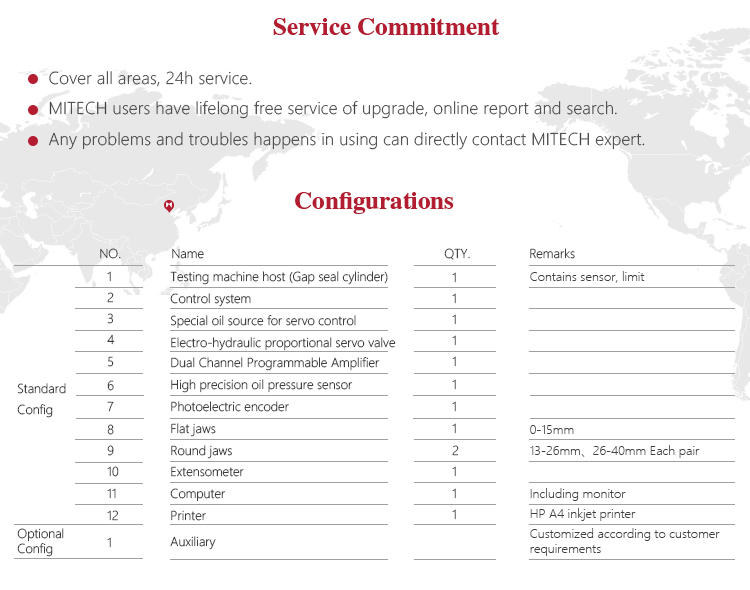

Function & application

Function & applicationl Quality control link of Metal processing manufacturing

l Quality control link of nonmetal manufacturing industry

l Teaching experiment of scientific research in Institutions of higher learning

l Material analysis test of scientific research institutions

l Quality inspection link of Quality inspection department

Working Principle

Working PrincipleTest machine is the product of test machine technology and mechanical transmission technology, sensor technology and automatic control technology and so on. It consists of three parts: drive system, control system and measurement system.The drive system is mainly used for the movement of the beam of the testing machine, through the control valve to adjust the beam movement;the control system is operated by the console control testing machine, and the state of the testing machine and the test parameters can be obtained through the display screen;the measuring system uses force sensor, signal amplifier, photoelectric encoder and data processing system to measure force, deformation and beam displacement.Drive system, control system, measurement system and other subsystems coordinate with each other to complete the material pull, pressure, bending and other mechanical performance testing.

Working Conditions

Working Conditionsl Operation Temperature:Ambient temperature~45℃;

l Relative humidity:20%~80%;

l In an environment free from vibration, corrosive medium and high magnetic field;

l Installed on a flat basis.

l Power supply voltage fluctuation does not exceed 10% of rated voltage.

Instrument Features

Instrument Featuresl It is widely used in the fields of metal and nonmetal processing, manufacturing, quality inspection, quality inspection, scientific research and experiment in Institutions of higher learning and so on;

l Design integrated oil source design makes the whole structure more compact and reasonable, reducing the area;

l With display test force, test force peak, test force, speed and other functions;

l With the test force clear, peak hold, parameter settings, regardless of the whole file value measurement, calibration and fine tuning and other functions;

l Using 5000 wire photoelectric encoder, the displacement relative precision is high;

l Using high precision and high stability spoke tension and strain sensor, with high-precision measuring and amplifying system to ensure high precision of test force;

l Built-in controller to ensure that the test machine can be specimen deformation, test force and displacement of the closed-loop control;

l With limited protection function, automatic stop after reaching the limit, can prevent the collision when the middle crossbeam moves and cause overload or even damage the sensor;

l The built-in control card based on PCI technology can reduce the connection, improve the real-time control and real-time acquisition function, and improve the stability of the product;

l Self selection of load sensors or oil pressure sensors, which can effectively improve the range of test range and the accuracy of force value;According to the load size, it can switch the appropriate range to ensure the accuracy of measurement data automatically;

l Zero adjustment, calibration, storage and so on, without any analog adjustment link, the control circuit is highly integrated;

l At the end of the test, the test data and the test curve are saved automatically for subsequent retrieval and analysis;

l Can be batch test, the same parameters of the sample just have a one test set;

l Consistent with GB, ISO, ASTM, DIN and other related standards at home and abroad.

Operating Method and Attentions

Operating Method and Attentions Instrument Maintenance

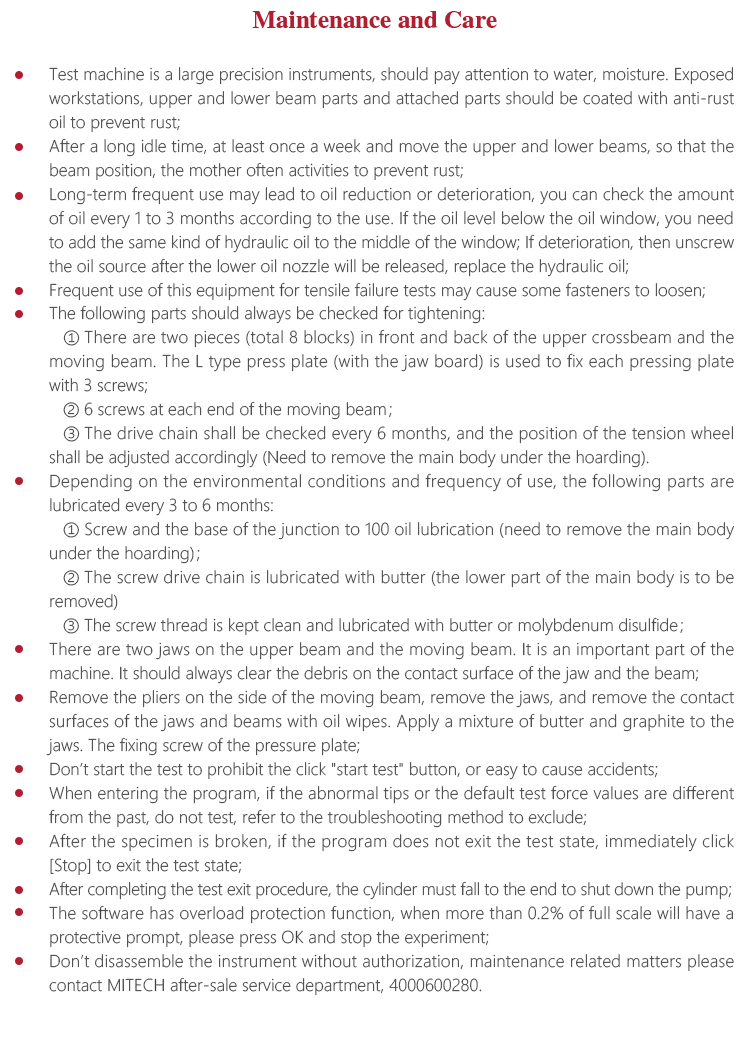

Instrument Maintenance<!--[if !supportLists]--> l <!--[endif]-->Test machine is a large precision instruments, should pay attention to water, moisture. Exposed workstations, upper and lower beam parts and attached parts should be coated with anti-rust oil to prevent rust;

<!--[if !supportLists]-->l <!--[endif]-->If idle for a long time,turn on and move the upper and lower beams, so that beam position, silk mother often active to prevent rust at least once a week

<!--[if !supportLists]-->l <!--[endif]-->Long term frequent use may cause oil decreasing or deteriorating,the amount of oil should be checked every 1~3 months in accordance with the use,if the oil surface is lower than the oil window you need to add the same kind of hydraulic oil to the middle of the window;if the oil has deteriorated, then remove the special oil source after the lower part of the oil nozzle to release and replace the hydraulic oil;

<!--[if !supportLists]-->l <!--[endif]-->Frequent use of this equipment for tensile failure test may cause some of the fasteners loose. The following parts should always be checked for tightening:

①There are two pieces (8 blocks) in front and back of the upper crossbeam and the moving beam. The L type press plate (with the jaw board) is used to fix each pressing plate with 3 screws;

②6 screws at each end of the moving beam;

③The drive chain shall be checked every 6 months, and the position of the tension wheel shall be adjusted accordingly;

<!--[if !supportLists]-->l <!--[endif]-->The following areas are lubricated every 3~6 months, depending on the environmental conditions and frequency of use:

①The combination of the screw and the frame is lubricated with grease No. 100 (removing the lower part of the main body panel);

②The screw drive chain is lubricated with grease (removing the lower part of the main panel);

③The screw threads are kept clean and lubricated with butter or molybdenum disulfide;

<!--[if !supportLists]-->l <!--[endif]-->Each of the upper cross beam and the moving crossbeam is provided with 2 jaws, and the clamping plate of the jaw is an important part of the machine,the sundries on the contact surface of the jaw plate and the cross member shall be removed frequently,remove the pliers on the side of the moving beam, remove the jaws,clean the contact surfaces of the jaw, pallet and crossbeam with oil cloth, and apply the proper amount of grease and graphite to the fastening plate;

<!--[if !supportLists]-->l <!--[endif]-->Do not start the test to prohibit the click "start test" button, or easy to cause accidents;

<!--[if !supportLists]-->l <!--[endif]-->When entering the program, if the abnormal prompt or the default test force value is different from the past, do not test, exclude the trouble refer to the troubleshooting;

<!--[if !supportLists]-->l <!--[endif]-->If the program does not exit the test state after the test is broken, click [Stop] to exit the test state immediately;

<!--[if !supportLists]-->l <!--[endif]-->After completing the test exit procedure,shut down the pump which the cylinder must fall to the end to ;

<!--[if !supportLists]-->l <!--[endif]-->The software has overload protection function, when more than 0.2% of full scale will have a protective prompt, please press OK and stop the experiment;

<!--[if !supportLists]-->l <!--[endif]-->Don’t disassemble the instrument without authorization, maintenance related matters please contact MITECH after-sale service department with 4000600280.

-

-

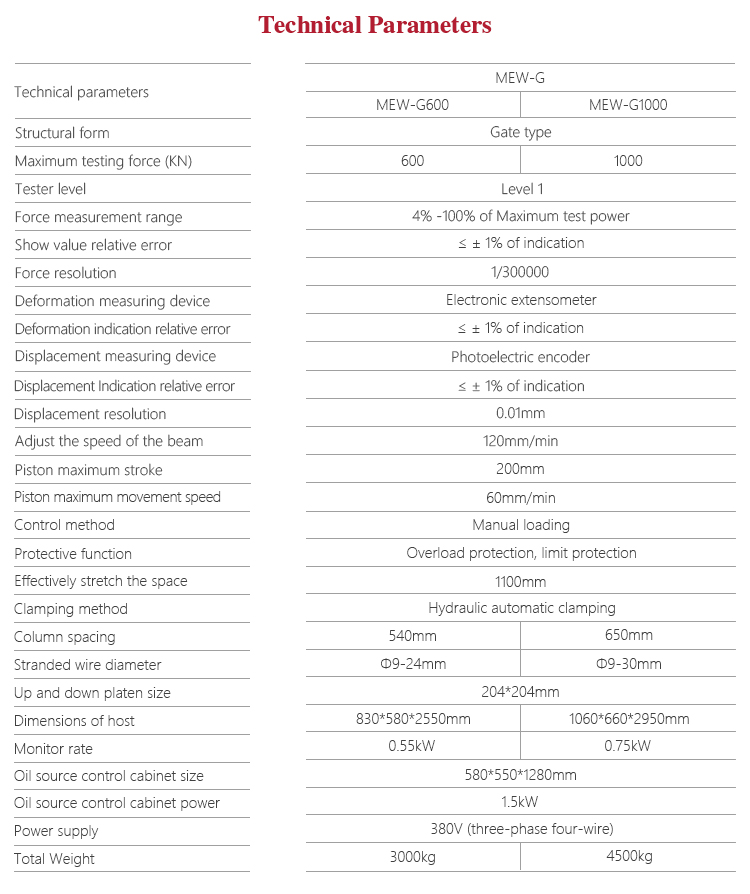

Structural form Gate type Maximum testing force (KN) 1000 Tester level Level 1 Force measurement range 4% -100% of Maximum test power Show value relative error ≤ ± 1% of indication Force resolution 1/300000 Deformation measuring device Electronic extensometer Deformation indication relative error ≤ ± 1% of indication Displacement measuring device Photoelectric encoder Displacement Indication relative error ≤ ± 1% of indication Displacement resolution 0.01mm Adjust the speed of the beam 120mm/min Piston maximum stroke 200mm Piston maximum movement speed 60mm/min Control method Manual loading Protective function Overload protection, limit protection Effectively stretch the space 1100mm Clamping method Hydraulic automatic clamping Column spacing 650mm Stranded wire diameter Φ9-30mm Up and down platen size 204*204mm Dimensions of host 1060*660*2950mm Monitor rate 0.75kW Oil source control cabinet size 580*550*1280mm Oil source control cabinet power 1.5kW Power supply 380V (three-phase four-wire) Total Weight 4500kg -

-