Product

Overview

Overview Graphic

Graphic Technical

Technical Configuration

Configuration Related

Related

Product

- Overview

- Graphic

- Technical

- Configuration

- Related

-

Product Overview

Product OverviewMitech MUV-2Y automatic hydraulic broaching machine, through the Single chip control processing gap, taking the hydraulic transmission of the double knife structure, double pole double position,a processing drawing molding, the processing quality is reliable and good identity; Broach with high hardness, wear good, long life which made by special materials and special process precision manufacturing. The hydraulic broaching machine for the impact test of professional configuration equipment,specifically for the impact of the sample V-notch and U-notch processing.It is the necessary professional precision testing equipment for improving production efficiency and saving production costs.

Function & application

Function & applicationProfessional for the impact of sample V-notch and U-notch processing

Working Principle

Working Principle Working Conditions

Working Conditionsl Operation Temperature:Ambient temperature~45℃;

l Relative humidity:20%~80%;

l In an environment free from vibration,corrosive medium and high magnetic field

l Installed on a flat basis.

l Power supply voltage fluctuation does not exceed 10% of rated voltage.

Instrument Features

Instrument Featuresl Used for the impact of sample V-notch and U-notch processing;

l With features of novel shape, strong structure, high reliability, simple operation;

l Take the hydraulic transmission of the double knife structure, double pole double position,a processing drawing molding,

the processing quality is reliable and good identity;

l The broach with high hardness, good wear resistance, long life which made by special materials and special process precision

manufacturing, each knife can be processed about 20,000 samples;

l Simple and reliable operation, high efficiency;

l Sample gap processing only need 8 seconds, easy to operate and reliable,with high efficiency;

l Consistent with GB2106-80、GB229-94-2007、ASTM E23、EN10045、ISO148、ISO0083 and other relevant domestic and

foreign standards.

Operating Method and Attentions

Operating Method and Attentions Instrument Maintenance

Instrument Maintenancel Before using the instrument, please read the instruction manual carefully, understand the operation steps and precautions,to

avoid the damage caused by improper operation or personal safety accident;

l Before each boot should be used to inject a small amount of oil gun around the knife box into a small amount of oil;

l Oil return valve is strictly prohibited to adjust. If you want to adjust to the clamp at the oil can flow to the knife is appropriate,

the return valve should not be too small, otherwise the pump motor easy to burn;

l After the drawing is completed, the clamp must be released to remove the specimen before allowing the broach to rise;

l Each time of the sample processed, it is necessary to clean up the iron scrap on the cutting edge so as not to affect the

processing quality.

l Replace the new knife, you must re-adjust the clamp to ensure that the depth of the specimen gap appropriate;

l Don’t disassemble the instrument without authorization, maintenance related matters please contact MITECH after-sale

service department with 4000600280.

-

-

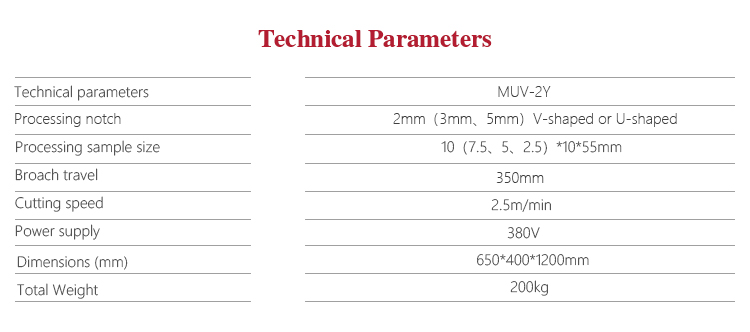

Processing gap 2mm(3mm、5mm))V-shaped or U-shaped Processing sample size 10(7.5、5、2.5)*10*55mm Broach travel 350mm Cutting speed 2.5m/min Power supply 380V Dimensions 650*400*1200mm Total Weight 200kg -

-