Product

Overview

Overview Graphic

Graphic Technical

Technical Configuration

Configuration Related

Related

Product

- Overview

- Graphic

- Technical

- Configuration

- Related

-

Product Overview

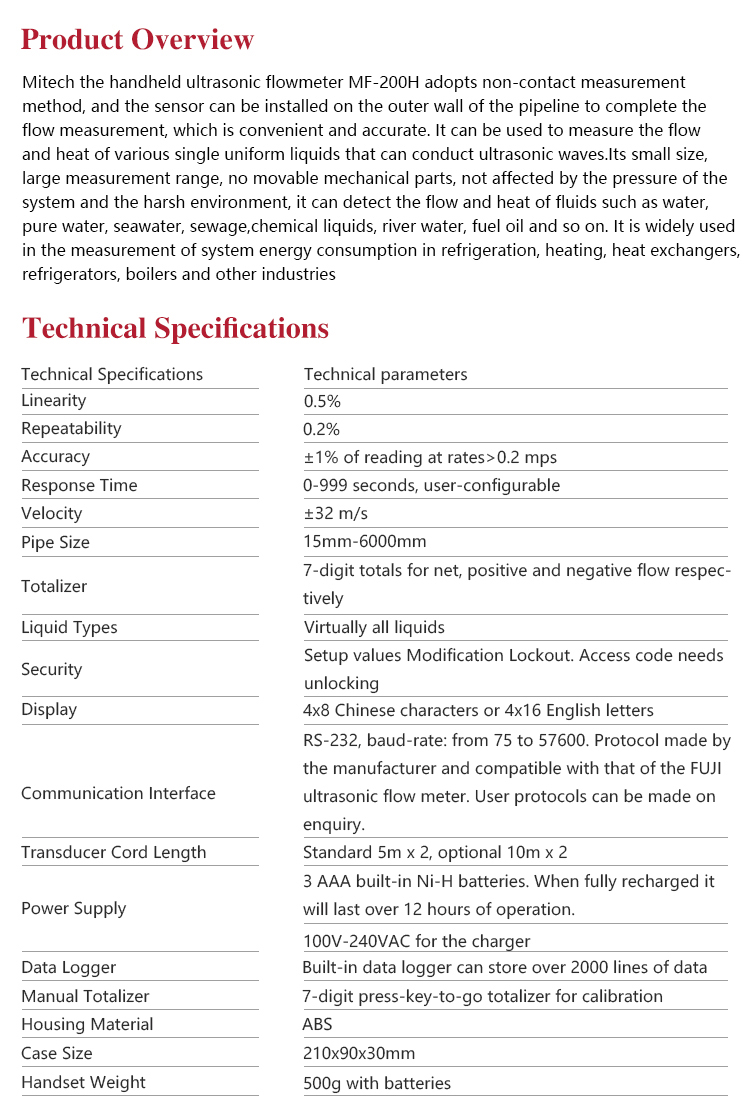

Product OverviewMitech handheld ultrasonic flowmeter MF-200H adopts non-contact measurement method, and the sensor can be installed on the outer wall of the pipeline to complete the flow measurement, which is convenient and accurate. It can be used to measure the flow and heat of various single uniform liquids that can conduct ultrasonic waves. Its small size, large measurement range, no movable mechanical parts, not affected by the pressure of the system and the harsh environment, it can detect the flow and heat of fluids such as water, pure water, seawater, sewage, chemical liquids, river water, fuel oil and so on. It is widely used in the measurement of system energy consumption in refrigeration, heating, heat exchangers, refrigerators, boilers and other industries.

Function & application

Function & application

Measurement of fluids such as water, pure water, seawater, sewage, and river water;

Measurement of chemical liquid, fuel oil and other fluids;

Other fluid measurement work for single uniform liquid capable of conducting ultrasonic waves

Working Principle

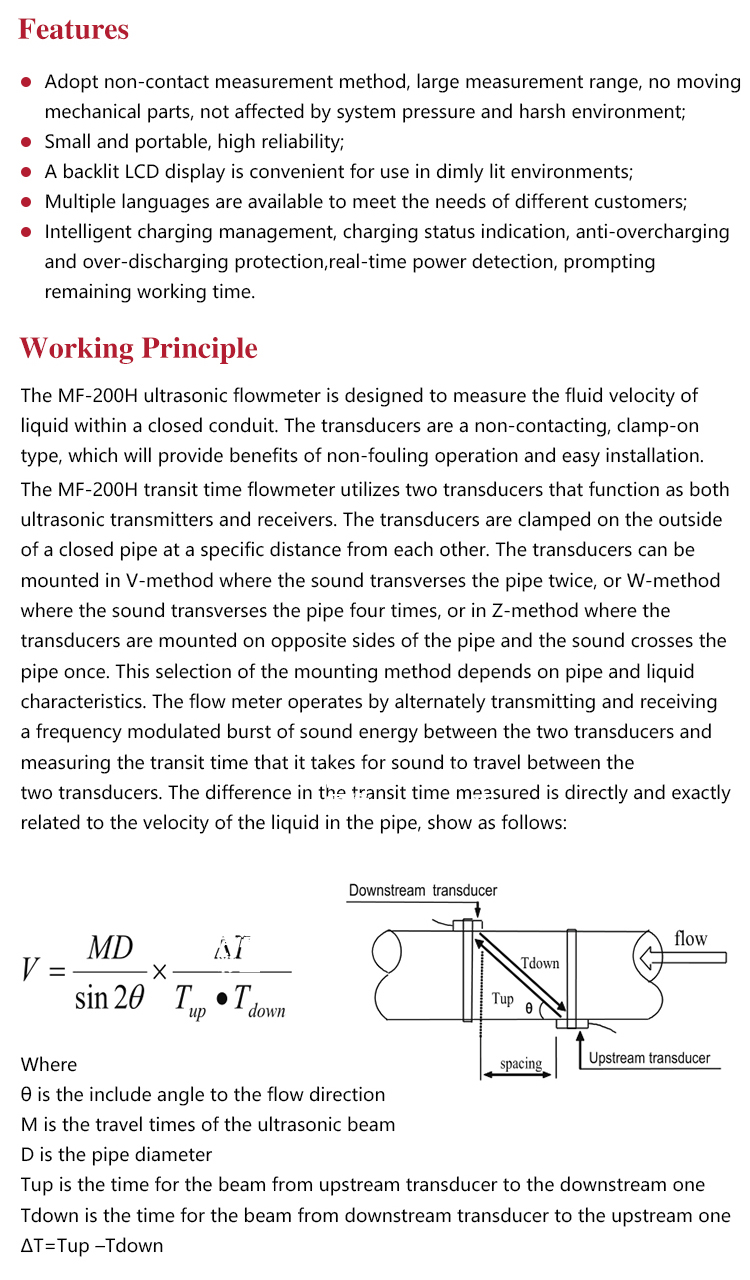

Working PrincipleThe MF-200H ultrasonic flowmeter is designed to measure the fluid velocity of liquid within a closed conduit. The transducers are a non-contacting, clamp-on type, which will provide benefits of non-fouling operation and easy installation.

The MF-200H transit time flowmeter utilizes two transducers that function as both ultrasonic transmitters and receivers. The transducers are clamped on the outside of a closed pipe at a specific distance from each other. The transducers can be mounted in V-method where the sound transverses the pipe twice, or W-method where the sound transverses the pipe four times, or in Z-method where the transducers are mounted on opposite sides of the pipe and the sound crosses the pipe once. This selection of the mounting method depends on pipe and liquid characteristics. The flow meter operates by alternately transmitting and receiving a frequency modulated burst of sound energy between the two transducers and measuring the transit time that it takes for sound to travel between the two transducers

Working Conditions

Working ConditionsOperating temperature: ﹣20℃ ~ +50℃;

Storage temperature: -30℃~+70℃;

Relative humidity: ≤90%;

There is no strong vibration, strong magnetic field, corrosive medium and severe dust in the surrounding environment

Instrument Features

Instrument FeaturesAdopt non-contact measurement method, large measurement range, no moving mechanical parts, not affected by system pressure and harsh environment;

Small and portable, high reliability;

A backlit LCD display is convenient for use in dimly lit environments;

Multiple languages are available to meet the needs of different customers;

Intelligent charging management, charging status indication, anti-overcharging and over-discharging protection, real-time power detection, prompting remaining working time.

Operating Method and Attentions

Operating Method and Attentions Instrument Maintenance

Instrument Maintenance -

-

Linearity 0.5% Repeatability 0.2% Accuracy ±1% of reading at rates>0.2 mps Response Time 0-999 seconds, user-configurable Velocity ±32 m/s Pipe Size 15mm-6000mm Totalizer 7-digit totals for net, positive and negative flow respectively Display 4x8 Chinese characters or 4x16 English letters -

-