Product

Overview

Overview Graphic

Graphic Technical

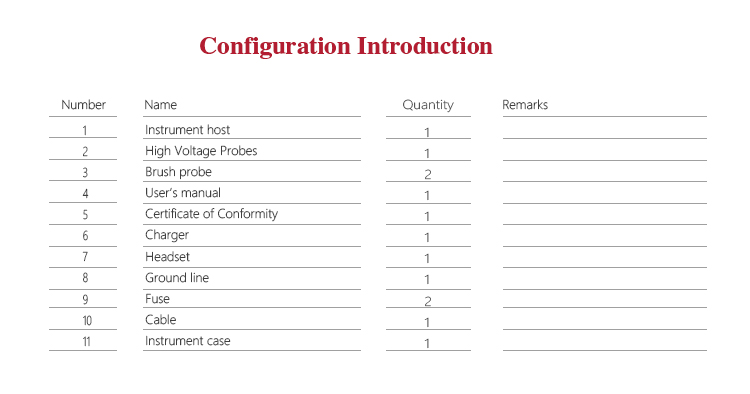

Technical Configuration

Configuration Related

Related

Product

- Overview

- Graphic

- Technical

- Configuration

- Related

-

Product Overview

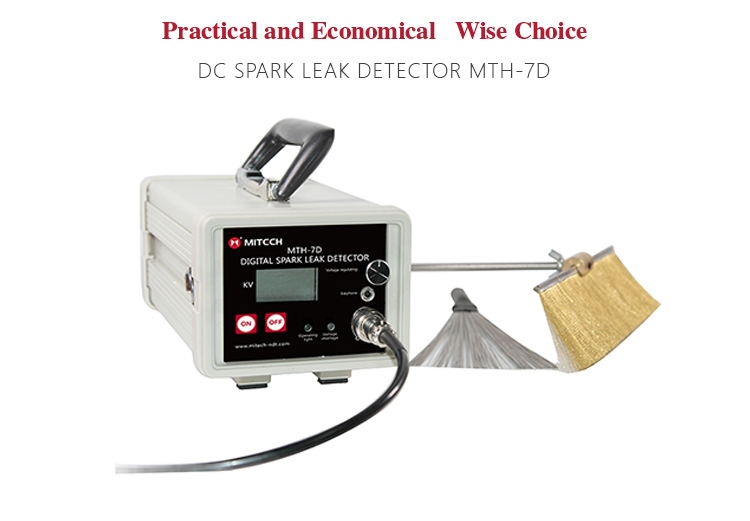

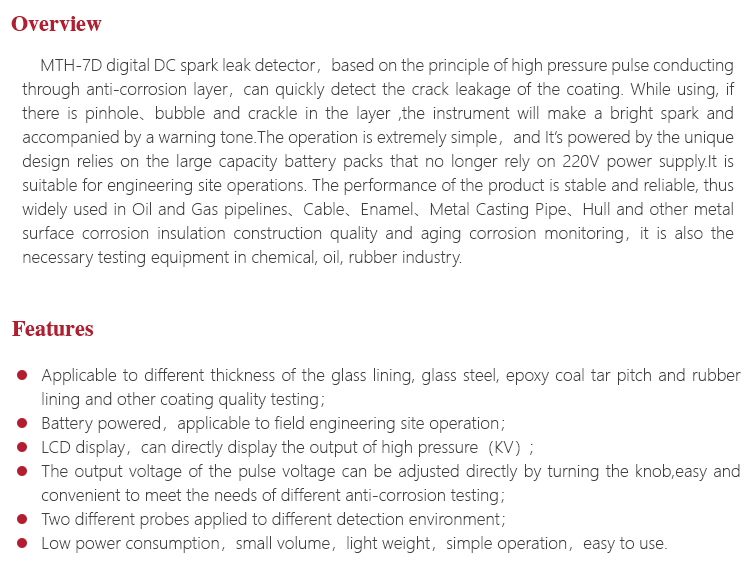

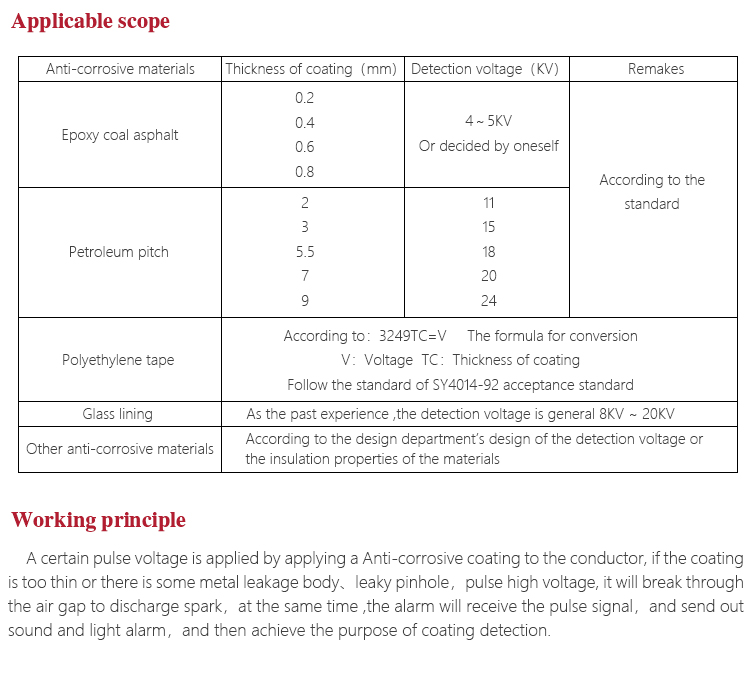

Product OverviewMTH-7D digital DC spark leak detector,based on the principle of high pressure pulse conducting through anti-corrosion layer,can quickly detect the crack leakage of the coating. While using, if there is pinhole、bubble and crackle in the layer ,the instrument will make a bright spark and accompanied by a warning tone.The operation is extremely simple,and It’s powered by the unique design relies on the large capacity battery packs that no longer rely on 220V power supply.It is suitable for engineering site operations. The performance of the product is stable and reliable, thus widely used in Oil and Gas pipelines、Cable、Enamel、Metal Casting Pipe、Hull and other metal surface corrosion insulation construction quality and aging corrosion monitoring,it is also the necessary testing equipment in chemical, oil, rubber industry.

Function & application

Function & application

Can detect the glass fence outside the wall, the valve pipe, glass pipe, epoxy coal asphalt, rubber lining and other cracks in the crack quickly.

Working Principle

Working PrincipleA certain pulse voltage is applied by applying a Anti-corrosive coating to the conductor, if the coating is too thin or there is some metal leakage body、leaky pinhole,pulse high voltage, it will break through the air gap to discharge spark,at the same time ,the alarm will receive the pulse signal,and send out sound and light alarm,and then achieve the purpose of coating detection.

Working Conditions

Working ConditionsMeasured at the room temperature,the surrounding environment has no moisture and corrosive gases.

Instrument Features

Instrument Featuresl Applicable to different thickness of the glass lining, glass steel, epoxy coal tar pitch and rubber lining and other coating quality testing;

l Battery powered,applicable to field engineering site operation;

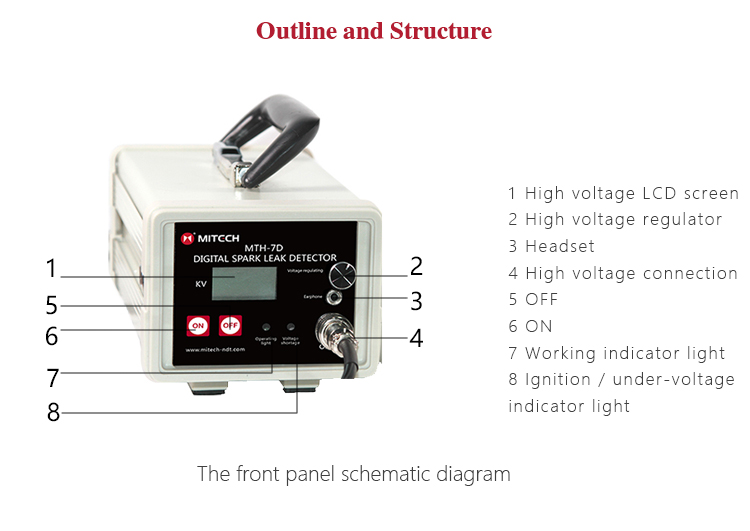

l LCD display,can directly display the output of high pressure(KV);

l The output voltage of the pulse voltage can be adjusted directly by turning the knob,easy and convenient to meet the needs of different anti-corrosion testing;

l Two different probes applied to different detection environment;

l Low power consumption,small volume,light weight,simple operation,easy to use.

Operating Method and Attentions

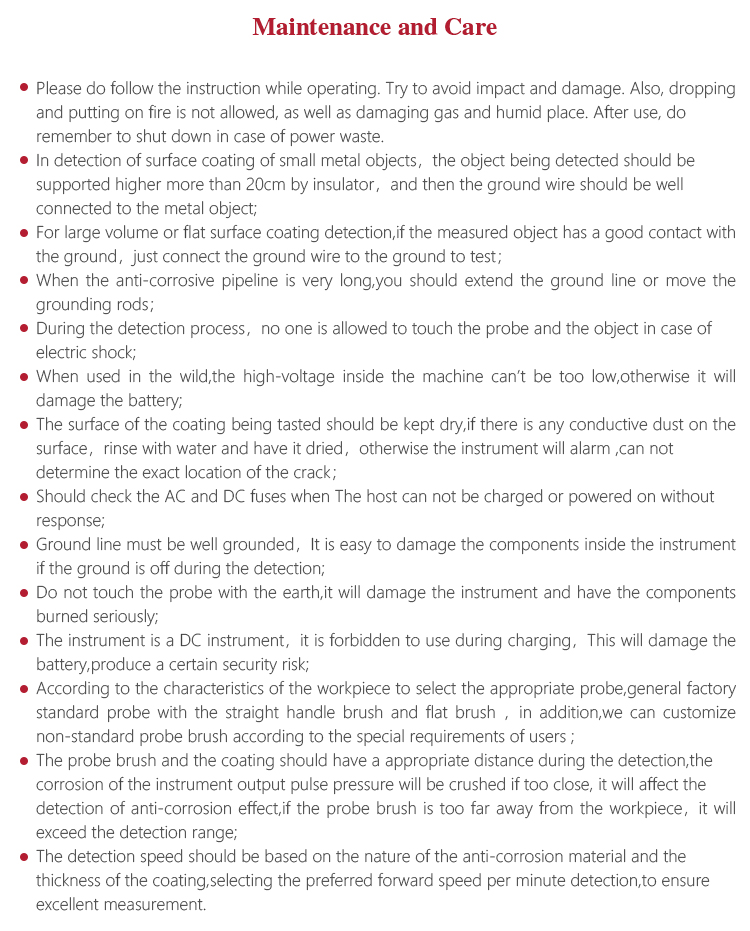

Operating Method and Attentions Instrument Maintenance

Instrument Maintenancel Please do follow the instruction while operating. Try to avoid impact and damage. Also, dropping and putting on fire is not allowed, as well as damaging gas and humid place. After use, do remember to shut down in case of power waste.

l In detection of surface coating of small metal objects,the object being detected should be supported higher more than 20cm by insulator,and then the ground wire should be well connected to the metal object;

l For large volume or flat surface coating detection,if the measured object has a good contact with the ground,just connect the ground wire to the ground to test;

l When the anti-corrosive pipeline is very long,you should extend the ground line or move the grounding rods;

l During the detection process,no one is allowed to touch the probe and the object in case of electric shock;

l When used in the wild,the high-voltage inside the machine can’t be too low,otherwise it will damage the battery;

l The surface of the coating being tasted should be kept dry,if there is any conductive dust on the surface,rinse with water and have it dried,otherwise the instrument will alarm ,can not determine the exact location of the crack;

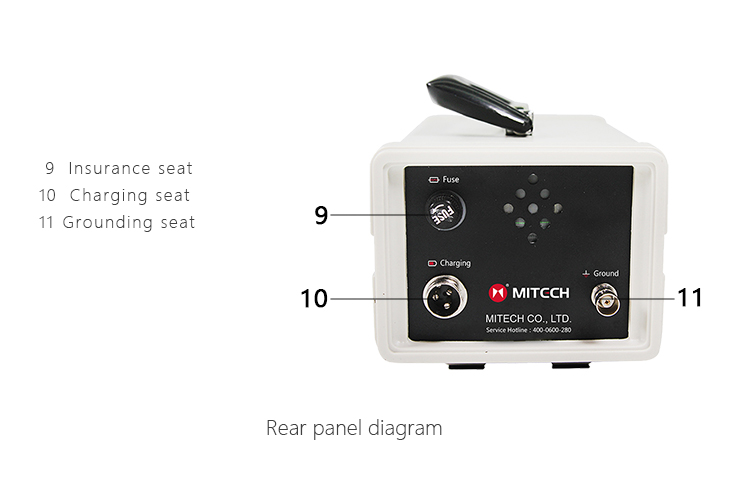

l Should check the AC and DC fuses when The host can not be charged or powered on without response;

l Ground line must be well grounded,It is easy to damage the components inside the instrument if the ground is off during the detection;

l Do not touch the probe with the earth,it will damage the instrument and have the components burned seriously;

l The instrument is a DC instrument,it is forbidden to use during charging,This will damage the battery,produce a certain security risk;

l According to the characteristics of the workpiece to select the appropriate probe,general factory standard probe with the straight handle brush and flat brush ,in addition,we can customize non-standard probe brush according to the special requirements of users ;

l The probe brush and the coating should have a appropriate distance during the detection,the corrosion of the instrument output pulse pressure will be crushed if too close, it will affect the detection of anti-corrosion effect,if the probe brush is too far away from the workpiece,it will exceed the detection range;

l The detection speed should be based on the nature of the anti-corrosion material and the thickness of the coating,selecting the preferred forward speed per minute detection,to ensure excellent measurement.

-

-

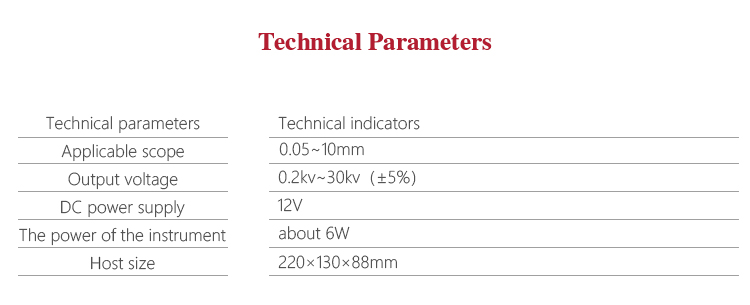

Host size 220×130×88mm C power supply 12V Output voltage 0.2kv~30kv(±5%) Applicable scope 0.05~10mm -

MTH-7D DC Spark Leak Detector MTH-7D digital DC spark leak detector,based on the principle of high pressure pulse conducting through anti-corrosion layer,can quickly detect the crack leakage of the coating. While using, if there is pinhole、bubble and crackle in the layer ,the instrument will make a bright spark and accompanied by a warning tone.The operation is extremely simple,and It’s powered by the unique design relies on the large capacity battery packs that no longer rely on 220V power supply.It is suitable for engineering site operations. The performance of the product is stable and reliable, thus widely used in Oil and Gas pipelines、Cable、Enamel、Metal Casting Pipe、Hull and other metal surface corrosion insulation construction quality and aging corrosion monitoring,it is also the necessary testing equipment in chemical, oil, rubber industry.

-

MTH-7D DC Spark Leak Detector MTH-7D digital DC spark leak detector,based on the principle of high pressure pulse conducting through anti-corrosion layer,can quickly detect the crack leakage of the coating. While using, if there is pinhole、bubble and crackle in the layer ,the instrument will make a bright spark and accompanied by a warning tone.The operation is extremely simple,and It’s powered by the unique design relies on the large capacity battery packs that no longer rely on 220V power supply.It is suitable for engineering site operations. The performance of the product is stable and reliable, thus widely used in Oil and Gas pipelines、Cable、Enamel、Metal Casting Pipe、Hull and other metal surface corrosion insulation construction quality and aging corrosion monitoring,it is also the necessary testing equipment in chemical, oil, rubber industry.